Description

What is Marine Plywood?

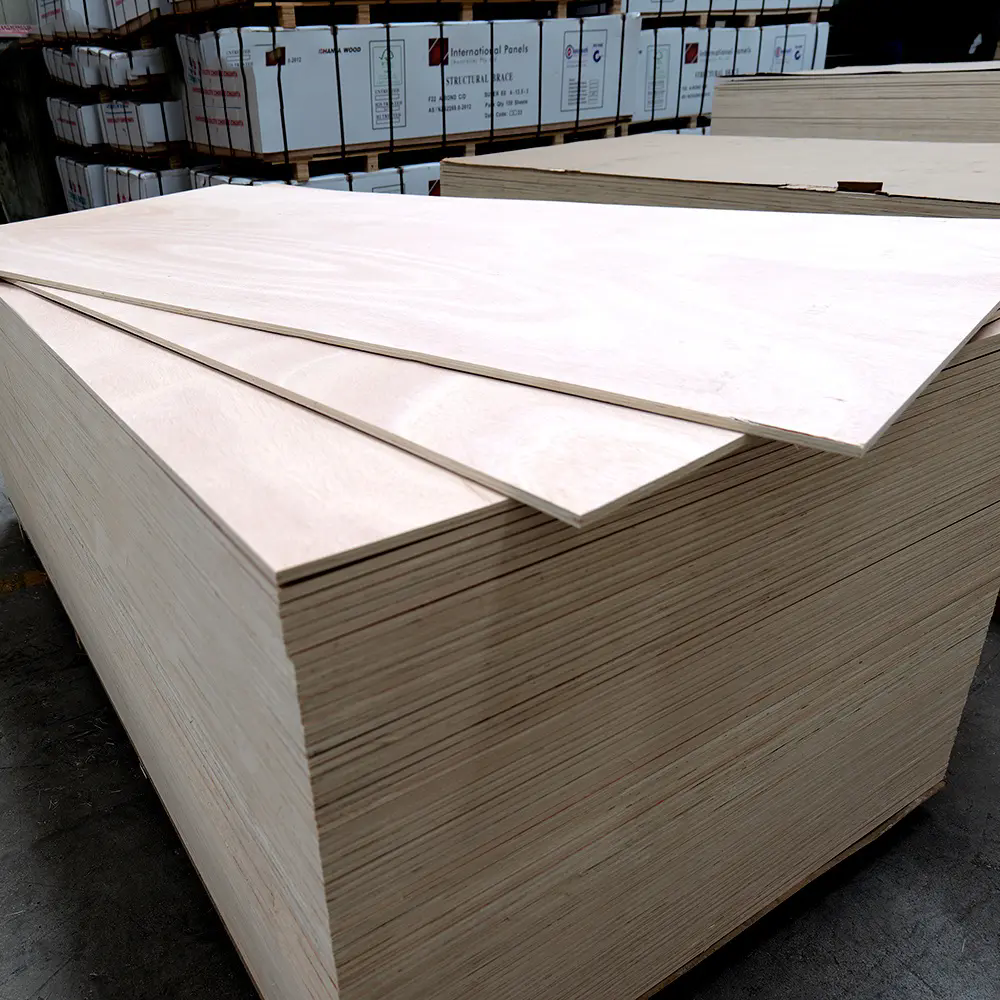

Marine plywood is a type of plywood made with waterproof glue and high-quality hardwood veneers. Its construction ensures minimal voids and excellent resistance to delamination. Often used in boats, docks, and exterior applications, marine plywood is built to last even in the most challenging conditions.

Chanta group marine plywood(Full okoume plywood), WBP glue, boiling water test more than 72 hours. It with excellent strength properties and waterproof for manufacture of canoes, boats or wall panels, interior claddings use. Decorative and joint-free plywood for interior design, wall panels and furniture. Safe and non-toxic it also suitable for woodworking and artists tools and laser and waterjet cutting. All marine plywood boards are made from tightly-peeled solid and joint-free okoume veneers.

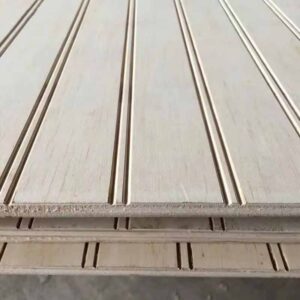

The face veneers are 0.5-1.5mm thick and core veneers 1.5mm thick. The joint-free face creates a beautiful panel with light, solid and homogeneous appearance. The panels can be waxed, stained, lacquered or even left as they are to showcase the light appearance of the raw wood and its unique grain pattern.

Key Features of Marine Plywood

- Water-Resistant Construction

Manufactured with WBP (Weather and Boil Proof) glue, marine plywood is highly resistant to moisture and water penetration. - High-Grade Material

Made from dense and durable hardwood species, it ensures a long-lasting performance with minimal wear and tear. - Minimal Core Gaps

The absence of gaps or voids in the inner layers enhances its strength and prevents water from seeping through. - Superior Surface Finish

The smooth, sanded surface is perfect for painting or applying protective coatings, offering additional weatherproofing. - FSC Certified and Eco-Friendly Options

It is available in eco-friendly varieties, ensuring sustainability without compromising on quality.

Reviews

There are no reviews yet.